PROCESS:

BRONZE

THE CASTING PROCESS

Creating a clay, plaster, wood or wax figure is only one step in the sculptural journey. Anomalies sometimes occur during the complicated casting process, that can be caused by any number of factors. To work with these anomalies, is as much reliant on the artistry of the foundry, as it is the artist.

Note: Bronze Process photos courtesy of Stephen Charnock (bronzecast.co.uk), unless stated otherwise.

SILICONE MOULDS

There are several types of mould, used in the production of sculpture. A silicon mould is most widely used as it can be re-used to make several editions of each piece. Layers of silicone are built up over the clay, the first coat picking up the surface detail. Depending on the size or complexity of the sculpture, the mould can be made in multiple sections, separated by shims and marked by keys, so they can later be connected back together.

WAX POSITIVE

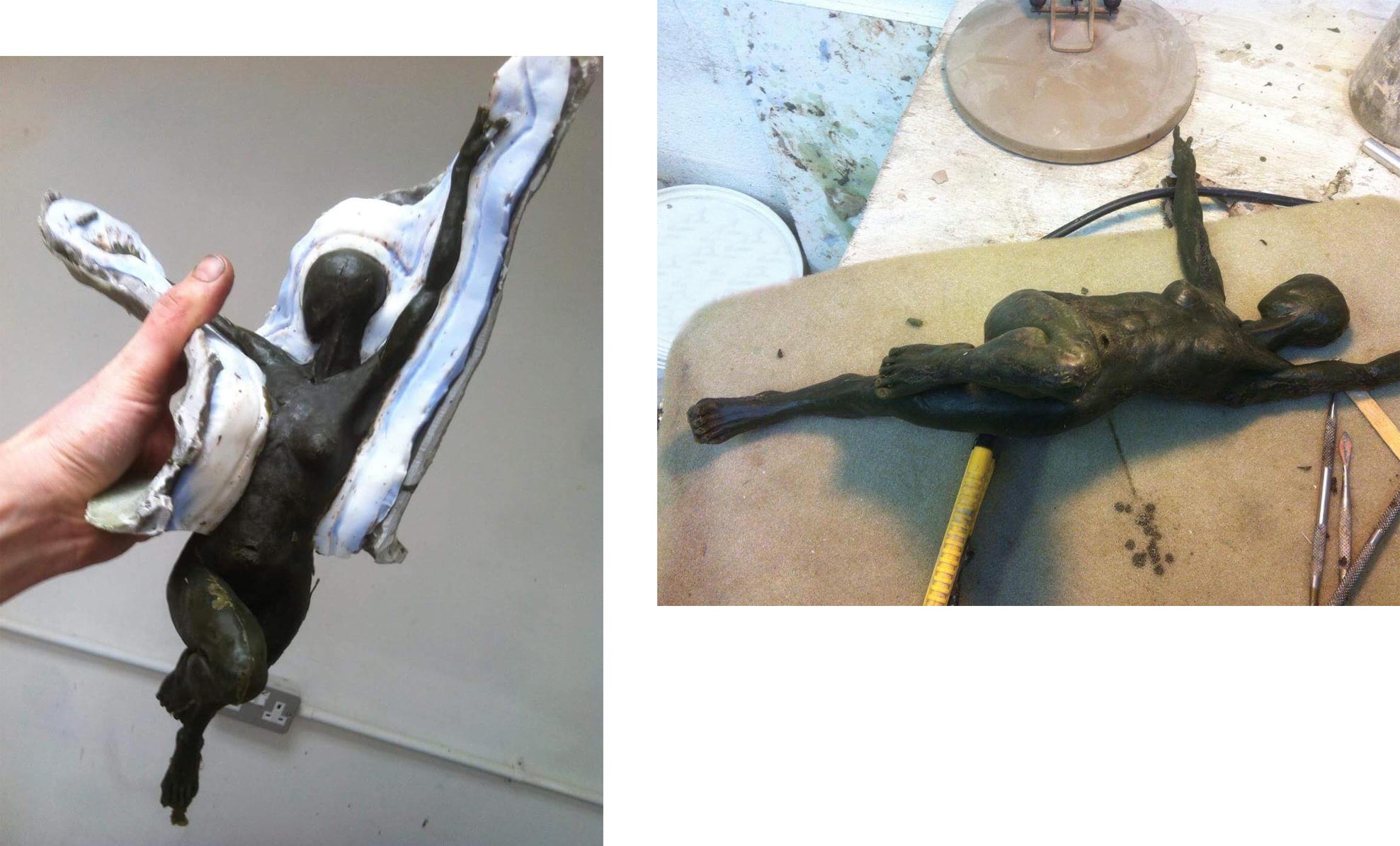

The mould creates a negative impression of the original sculpture. This is now used to create a wax positive copy of the piece. Melted wax is layered into the mould in thin layers. If there are several pieces of the mould, they are now stuck back together with melted wax. The resulting piece is a hollow wax copy of the original model.

Usually the wax model needs to be tidied up and any parts of the figure that have not been accurately copied are fixed or chased. The lines where the pieces of the wax model join together are worked so they are invisible.

CERAMIC SHELL

Once the wax model is made, strips of wax are attached to create gates. This is how the molten bronze will ultimately flow through the final shell mould, into the cavity left by the wax.

The ceramic shell is made by making layer after layer of slurry and ground porcelain, which is allowed to dry. Then the shell is fired, and the wax melts out of the shell, leaving a sculpture shaped cavity inside. It is this cavity that is filled with molten bronze to make the final sculpture.

FROM WAX TO BRONZE

Cherry red melted metal is poured into the ceramic shell and allowed to cool. Once cool the metal is hard, the shell is removed from the sculpture…with a sledgehammer.

FETTLING

For the most part the figure is similar to the original clay piece. But some areas will not be 100% perfect. These can be caused by air bubbles, impurities in the bronze or a flaw in the mould. These defects are rectified by fettling. This is generally a combination of skills. Some parts are built up by welding and then filed back down to the correct form. Sometimes parts are recast and welded back onto the main figure. When the weld lines are no longer visible, the piece is sandblasted to create a fine surface ready for patination.

PATINATION

Patinas are created by any mixture of chemicals and pigments to create an endless variety of finishes. Each chemical reacts differently with the properties of the metal, creating different colours and textures. Often heat is applied to bring the patination along. The application of the patina is an artform and it is generally built up in layers, using a combination of techniques.

Once the patina is completed the sculpture needs to be allowed to cool, then wax is applied, and the piece is attached to its base.